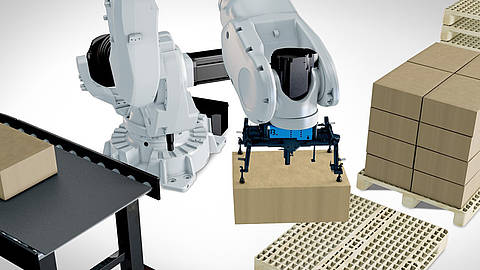

Robot Palletizing

Flexible solutions

Robotic palletizing and depalletizing can unleash tremendous savings. First, robotic palletizing modules can raise the capacity of any packing system up to 15 percent, depending on the products. Not only that, but the robots free up your employees to do other work as well.

Robotic palletizing stations cut costs, reduce error rates and make packing lines far more flexible and efficient. With our process visualisation, you can keep track of everything and closely monitor and manage your robot palletizing station.

Advantages at a glance

- Easy: Easy configuration of pallets and validation.

- Fast: Configuration using lists of saved elements.

- Visual: Visualization of the current status.

- Complete: Checking and configuration of all robot parameters, such as position or working speed.

- More: Checking additional devices such as conveyor belts.

High-tech process control

The process control technology sends all the data required to correctly palletize or depalletize products right to the robots or the PLC that controls the robots. It also monitors task progress in real time.

You can easily configure products on the pallets and validate the configuration with the software. The operator can then use the saved configuration to quickly generate all the settings for a palletizing job.

The process control user interface runs in a web browser and can be opened on any computer with adequate access permissions. That way, you can check the current status of the palletizing process from other stations. Security is provided by a sophisticated user administration and permission management system.