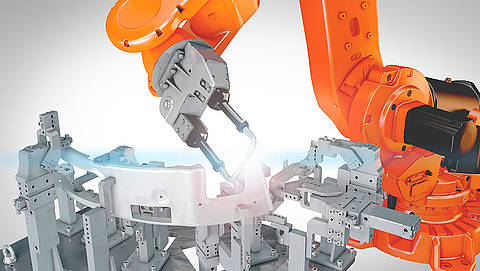

Welding For one-off and series production

Faster and better:

conventional welding with robots

Blumenbecker is your partner for the automation of a single welding workstation or a complete welding line. Welding robots can carry out a wide variety of conventional welding processes, such as TIG / MIG / MAG, plasma welding or special welding processes.

The high axis speeds of the robots ensure particularly low cycle times; unproductive movements between two welding seams are minimized. The high repeat accuracy guarantees an accurate approach to the beginning of the weld seam.

The advantages are a significantly improved weld seam quality as well as a significant reduction in machining time and thus an increase in productivity. In addition, employees are protected from harmful substances.

Robot welding is a linchpin of today's automotive industry. However, it has migrated into other areas, too. Robot welding systems are increasingly proving their value in and outside industrial mass production.

Discover the advantages of robot application welding

- Careful: No tool wear, no-touch welding.

- Easy: Components are easily accessible because the laser transmits power over long distances.

- Exact: Low thermal impact on material – minimal material distortion and structural change.

- Fast: Weld faster thanks to high power density.

- Strong: Very strong welds.

- Powerful: Deep welds with material thicknesses up to 25 mm.