Industrial-Service Complete protection for industrial equipment

Professional Maintenance

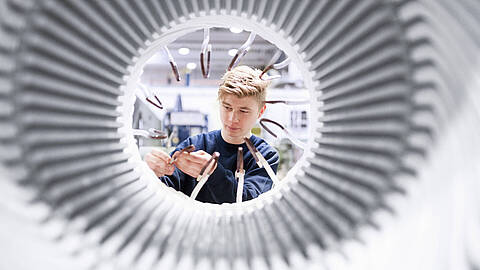

Your industrial machines and equipment require professional maintenance, inspections and servicing – that’s why we make sure our employees are thoroughly qualified and fully supported by specially equipped service vehicles.

They will keep your motors, generators, pumps, cranes, doors, lifting platforms, floor conveyors, load-handling attachments and other equipment running smoothly at all times.

Time and again, our customers have highlighted the knowledge, versatility and commitment of our employees. There’s a reason for that. We don’t view ourselves as a mere contractor but actively develop custom strategies and suggest ways to preserve the value of your investments.

Our employees are all certified industry professionals who hold all necessary qualifications and regularly attend continuing education seminars in order to stay on top of the latest industry developments.

Digital industrial service

From the digital inspection service to the extensive online maintenance portal, we offer you everything from a single source.

Read moreCertified safety

Our experts conduct many of the tests required by law and can immediately perform all necessary repairs. Major repairs are done at our state-of-the-art repair shops. We use only the latest measurement instruments and methodologies. All our work is seamlessly documented, with a digital copy given to you when we are done. Key steps are documented as digital documents and uploaded to our maintenance portal if you wish so that you can instantly look up the maintenance histories of your machinery and equipment.

Testing of switchgears

We can test your switchgear for compliance with all relevant regulations, too. In addition, we will analyse and certify your industry networks and inspect your equipment using thermographic scanners.

Testing of airport ground support equipment and rolling stock technology

One of our areas of expertise is the inspection, maintenance and repair of rolling stock maintenance gear and ground support equipment. If you wish, we can set up dedicated workshops at your airport to provide constant testing and maintenance.

Retrofitting of industrial robots

Our highly skilled team can service and repair electrical and mechanical sub-systems in all brands of industrial robots at our in-house repair shop.